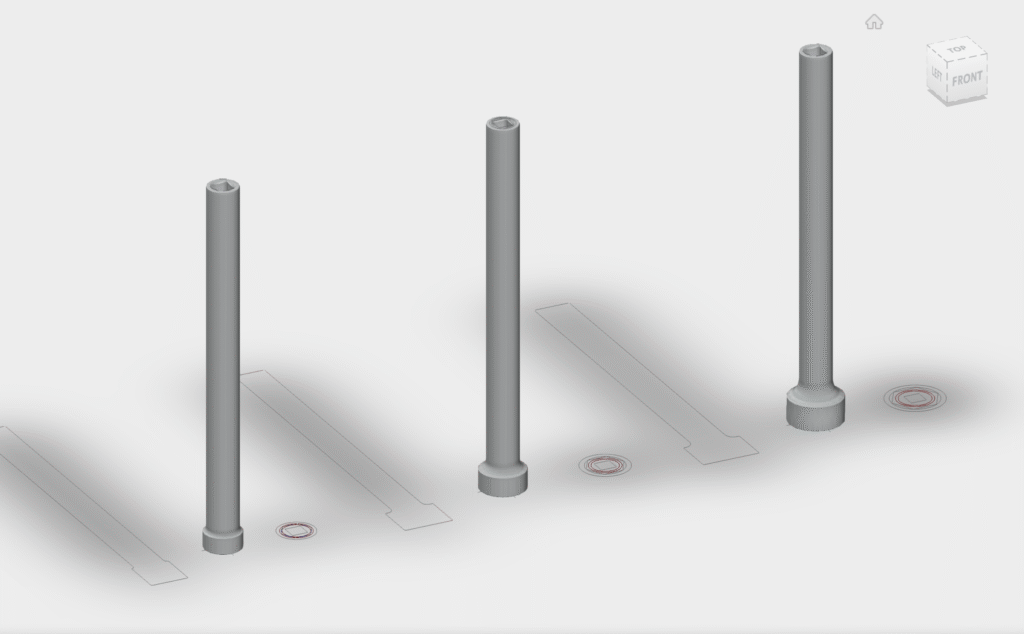

Finally, a Socket That Reaches What Others Can’t.

TorqueBuddy extended-length impact sockets are built for structural steel riggers, precision-machined, phosphate-coated, and engineered to tackle the toughest hold-down bolts on site.

Currently in development…

Building to deliver high-torque performance without the high price.

Power. Reach. Reliability. Built Into Every Socket.

From high-torque strength to extended lengths and real-world durability, TorqueBuddy delivers professional-grade performance trusted by structural riggers on site.

Unmatched Strength & High-Torque Precision

Extended Length for Every Job

Trusted by Riggers, Built for the Trade

What You’ll Get as an Early Supporter

TorqueBuddy is currently in development and we’re working directly with riggers to finalise lengths, materials, coatings, and sizing. By joining the early-access list, you help shape the final product – and secure benefits only available before launch.

Priority pricing on the first manufacturing run

Input into sizing, lengths, and custom requirements

Updates on testing, compliance, and release timelines

Register Your Interest Below

Frequently Asked Questions

Our FAQ section covers everything you need to know, including deep sockets, extended sockets, impact socket safety, and sizing standards.

1. What is a long socket?

A long socket (also called a deep socket) is a socket designed with extra length so it can reach nuts seated deeper inside assemblies or on long threads.

2. What’s the difference between a long socket and a deep sockets set?

A deep sockets set includes multiple deep or long sockets in different sizes, whereas a long socket refers to a single extended socket.

Deep socket sets are commonly used in automotive work, while long single sockets are often designed for specialty structural applications like the ones in your document.

3. What are the main types of sockets?

There are several types of sockets used across automotive and industrial applications:

Deep well sockets – Longer profile for long or recessed bolts

Impact sockets – Thick-walled, heavy-duty sockets for impact wrenches

Spark plug sockets – Long sockets with rubber inserts to protect plugs

Shallow sockets – Ideal for tight spaces

Hex sockets (6-point / 12-point) – Most common for hex-headed fasteners

Pass-through sockets – Hollow design for bolts that protrude past the nut

Universal/Flex sockets – Swivel design for 360° access in tight spaces

4. Are deep sockets more likely to break?

Deep sockets themselves are not more “breakable,” but regular chrome deep sockets can fail under impact loads.

Impact deep sockets have walls ~50% thicker, making them suitable for high-torque impact tools.

5. What is the purpose of deep sockets?

Deep sockets reach nuts on long bolts and recessed fasteners. They’re commonly used in:

Automotive engine work

Machinery maintenance

Any application where a shallow socket cannot reach the nut